PROFITABILITY + SUSTAINABILITY + ENERGY SAVING IN ONE PACKAGE

-

-

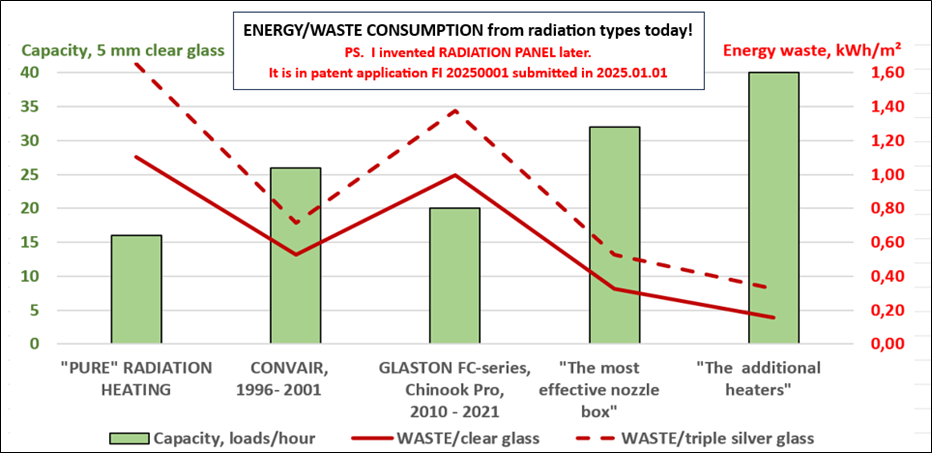

- I do not know what kind of profit might PURE RADIATION TYPE HEATING make. Mostly Chinese and KERAGLASS make ”convection heating ” tempering furnaces. It should be forbidden. It does not heat convection air. See below the graph. See ”Competition” of this website.

- GLASTON FC-series and even North Glass A-series claim, that they make optically fine, tempered glass with triple silver glass. FERACITAS has the same system. Nozzle boxes are in slight angle to the glass travel direction.

-

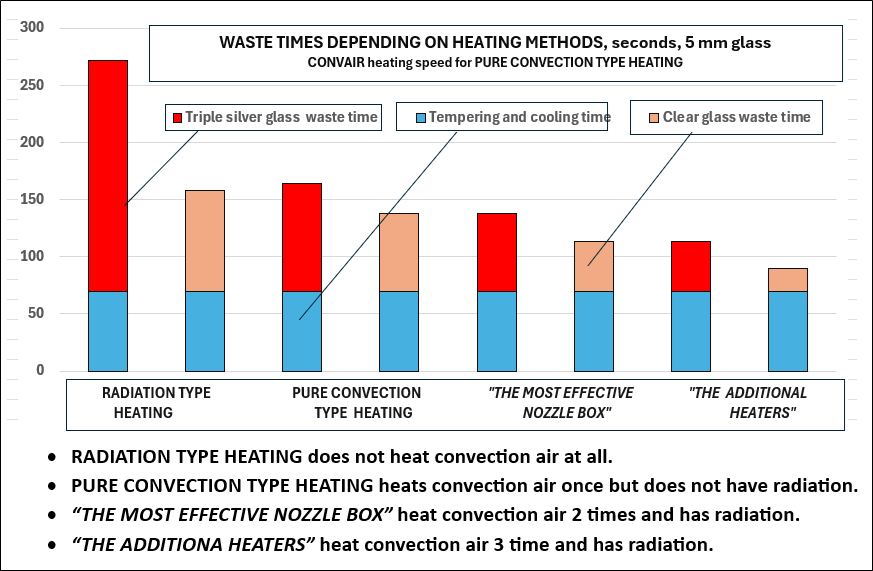

WASTE TIME = THE HEATING TIME – TEMPERING AND COOLING TIME

-

- The heating times and furnace heating method are as per the following graph. Tempering and cooling time is always the same!

- With waste time you lose: 1) additional production, (m²/hour), 2) operator and labor cost saving ($/hour ) and 3) + all the time energy is wasted: A) The convection blowers are and heat losses. B) The furnace and tempering take the whole of the tempering time C) The tempering blower efficiency about 60%. D) If the speed is reduced, or even stopped, starting takes and long for acceleration!

THERE ARE TWO (2) INVENTIONS

I. ”THE MOST EFFECTIVE NOZZLE BOX” I. The proof of the process!

-

-

-

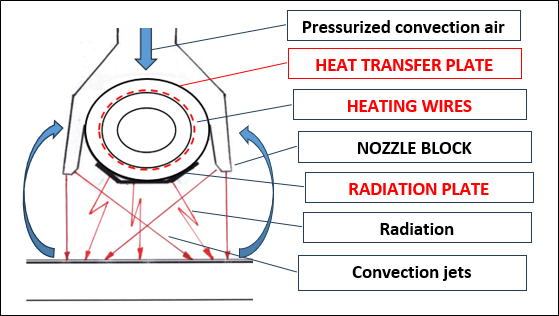

- I discovered 2021 the secret of CONVAIR in 2021 by patent application EP21159115.1. The HEAT TRANSFER PLATE protects bottom part HEATING WIRES from cooling effects of convection air. In 2021 I did not realize the importance of RADIATION PLATE. Therefore patent EP21159115.1 was applied.

- The HEATING WIRES cannot stand thermal shocks when cold glasses enter the furnace, if they are near the glass. The RADIATION PLATE protects them form that thermal shocks.

- See SHORT HISTORY OF CONVAIR. Otherwise you do not understand of how simple inventions are made.

-

-

-

-

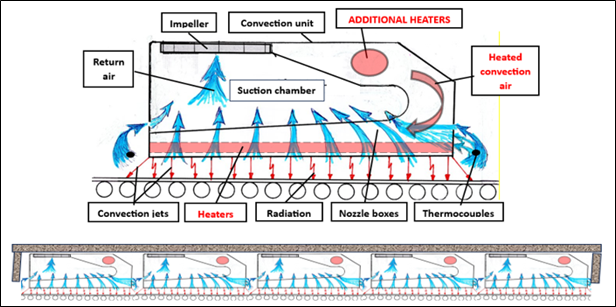

- Heating wires heat the RADIATION PANEL and the HEAT TRANSFER PLATE to a high temperature.

- The HEAT TRANSFER PLATE plate heats convection air by convection.

- The RADIATION PLATE is near the glass. Therefore, it radiates strong.

- The radiation plate is also thin. It heats fast. Therefore, radiation heating is more time effective.

- NOZZLE BLOCKS are near the glass. Convection is effective.

- RADIATION PLATES are removable. Heaters wire change is easy.

- Heating wires heat the RADIATION PANEL and the HEAT TRANSFER PLATE to a high temperature.

-

For every top heater needs one radiation plate. This is ”nothing” for benefits .

RADIATION PLATE patent application was made 2023-09-21. It was secret renewed by THE ADDITIONAL HEATERS date 2025-01-01.

II. ”THE ADDITIONAL HEATERS”, Unlimited heating speed

-

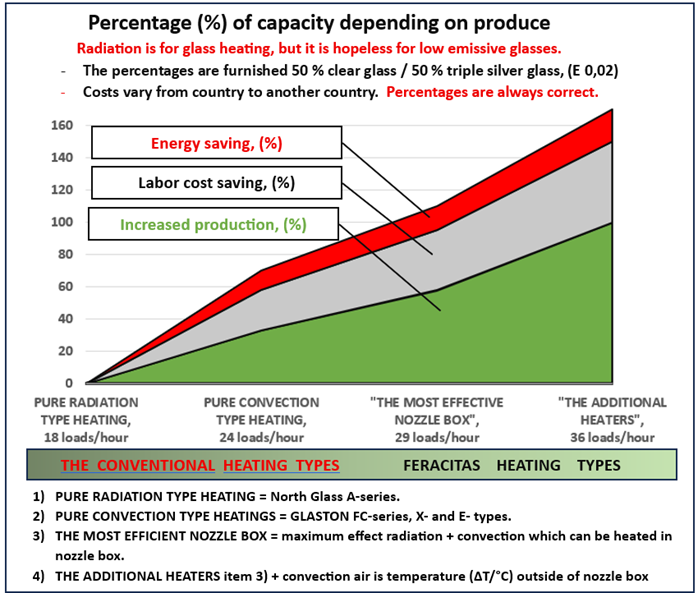

- THE ADDITIONAL HEATERS allows = ”unlimited” capacity = profit. The condition is, that glass thicknesses should be <= 12 mm. Then tempering and cooling time takes more time than the heating time.

- The heating time depends on the only how high temperature convection air can be heated. And what is the thickness when glasses break in the furnace.

- You can make build furnaces as long as you like. Continuing furnaces can be even more than 60 % shorter than radiation heating furnaces.

-

- Just one convection pipe (dia. 120 mm = 5″) with additional heaters in it can reach capacity as much as informed TECHNAL DATA. Additional heaters can be more if you like or bigger diameter.

- Also ADDITIONAL HEATERS heat the convection air. Therefore, it is ”double effect” compared to ”THE MOST EFFECTIVE NOZZLE BOX”.

- Why ”THE ADDITIONAL HEATER” heating speed is ”unlimited”? Formula of heating speed = capacity = h x A x (TSM – TCA).

-

- Where h = same for everyone, (heat transfer coefficient from sheet metal to convection air).

- A = convection area (m²),

- TSM = temperature of sheet metal to which heats the convection air and

- TCA = convection air temperature. This is the proof of unlimited heating speed.

-

- ”The additional heaters” costs one (1) additional heaters for one convection unit. Otherwise you should buy one (1) complete glass tempering furnace!

- ADDITIONAL HEATER was invented in 2024 and it renewed with priority year in 2025-01-01. It may not be invented prior and is is most likely granted!

CONVECTION UNIT ADVANTAGES,

-

- Both invention (I and II) are in preferably convection units.

- The thermocouples are more accurate and respond faster when they are in return air flow.

- Convection jets heat glass even between the convection units.

- Convection pressure is in the convection units which is a closed box. No leakage of hot convection air, no energy waste.

- The additional heaters are changed through the side walls and insulation.

- Additional heaters are in pipes in convection units. There is no convection pressure in the convection pipes. The same system is used in GLASTON FC-series E type but there is convection pressure in nozzle boxes. In FERACITAS it is easy. No sealing. Just change the additional heaters through the side walls and insulation.

- The nozzle boxes are in a small angle to the glass travel direction. The reason is optical quality of glass. GLASTON FC-series X-type and North Glass A-series have the same system.

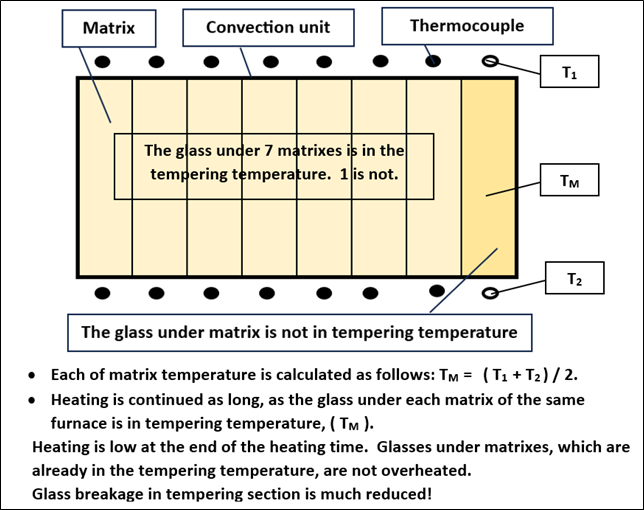

HEATING CONTROL

-

- Automatic sending to the tempering section is possible following the principle described under the graph. This is especially the heating process is based on the following of the furnace temperature of rather than than heating time (seconds).

- This is based on the advice of ex Tamglass product development directors, Pauli Reunamäki, who advised that calculation speed of computers was low in 30 years ago! This was the reason for thick radiation plates, 12 – 16 mm which CONVAIR used!.

TECHNICAL DATA

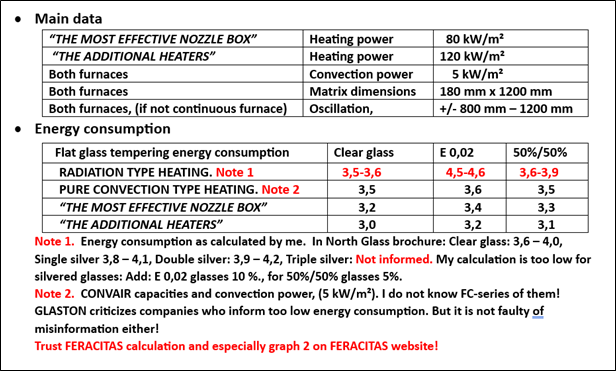

-

- Energy consumption is hard to measure in (kWh/m²). This is why it is used as the sales argument for tempering furnace sales. However, you must look at the heating speed = capacity of the furnace. The low capacity means high energy consumption.

- High convection power, over 10 kW/m² means energy consumption of 0,15 – 0,2 kWh/m², too.

- High heating power does not increase energy consumption. It rather saves it but increases kVA.

HISTORY OF GLASS HEATING The proof of the process

-

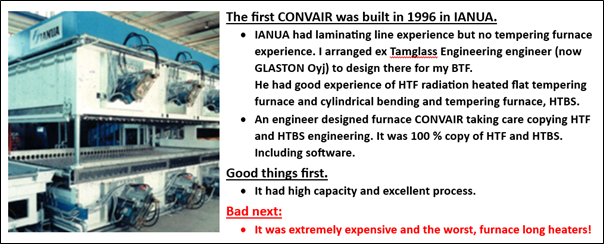

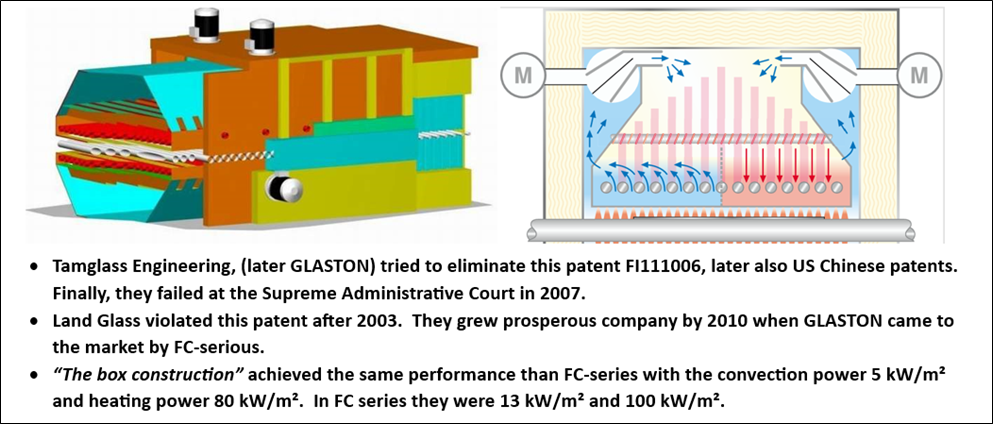

- CONVAIR was built 100% copy of Tamglass HTF/HTS/HTBS radiation furnaces. Even software! Radiation plates were thick, 16 mm. It was expensive to machine nozzle to them. Calculation speed of computers was low at 1990’ies. This was the reason that thick radiation plates were needed.

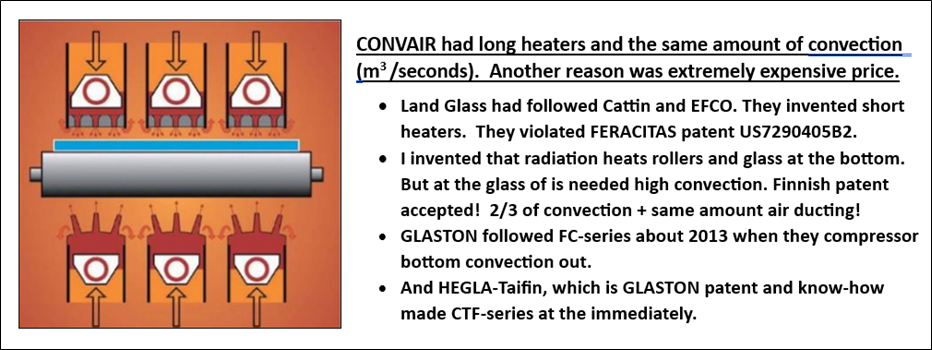

- At least EFCO and Cattin had developed open wire resistances. Short heaters and matrix convection, (radiation only). These turn from red to dark, although distance from glass is even 250 – 300 mm glass!

- Patent for CONVAIR was US 6470711B1 was wrong claimed! The claims should have been how to heat the convection air! Convection power was 5 kW/m² and heating power 80 kW/m². CONVAIR capacity was high. 5 mm clear glass was 26 loads/hour and triple silver glass at least 22 loads/hour. CONVAIR was supposed to be convection + radiation heating process. But was ”pure” convection heating furnace. It had effective convection air was heated once but no radiation. Then Tamglass Engineering did not know of short heaters. They were as long as the heating length.

- In 2003 GLASSROBOTS RoboTemp tried to increase CONVAIR capacity. Otherwise it was principally copy of CONVAIR with small differences. It had the same problems. RoboTemp convection power to was increased 10 kW/m². The capacity remained the same. Patent document US7448232B2. It was basically CONVAIR copy. Convection, (no radiation).

- In 2010 GLASTON tried to increase capacity even further by own development. It increased convection power to 13 kW/m² and heating power to almost 100 kW/m². It was a copy of RoboTemp and CONVAIR but with matrix heated convection air. In 2021, when I invented ”THE MOST EFFECTIVE NOZZLE BOX I informed GLASTON that their patent US8618442B2 eliminated convection heating and radiation. The capacity was reduced 30%.

- Clear glass capacity was 20 loads/hour, E 0,02 capacity was 16 loads/hour. Informed energy consumption were: Clear glass, 3,0 kWh/m², E 0,02. 3,3 kWh/m². They should have been 3,8 kWh/m² and 4,2 kWh kWh/m² according to the capacity and convection power.

- FERACITAS/Risto Nikander understood in 2021 CONVAIR process correctly. Patent application EP 21159115.1. I did not realize FI20230055. Convection air is heated once + radiation! “The most effective nozzle box”.

- FERACITAS /Risto Nikander understood in 2023 that convection capacity has no limits! Patent application FI20250001. Convection air is heated 3 times + radiation. “The additional heaters”, including priority of FI20230055.

- It took almost 25 years to recover CONVAIR secret and 27 years to have radiation + convection put together!

- 2 latest ”FERACITAS” patent applications are pending.

CHEAPER CONVAIR I, box construction

CHEAPER CONVAIR II, bottom convection

CONCLUSION

It is very hard to invent simplest and the best working solutions. In reality, 90 – 99% of technology exist. Simple 1 – 10% inventions can make wonders.