Product Manager for Bending and Tempering Equipment Tamglass Engineering Oy (now GLASTON Oyj)

In the end of 1980’ies and in 1990’ies GLASTON Oyj made very profitable business with HTF flat tempering furnaces and ESU windscreen bending furnaces. It had a new, even higher margin product, HTBS, for door glasses of cars.

The product development team failed to develop a car rear glasses machine. It is much more difficult process than HTBS. I invented in 1990 a simple system, later called BTF, (Bending and Tempering Furnace). The development team did not want BTF. The management did not understand the technology. Development team proposed CBTS. In my opinion a bad process. This created a dispute. Further, I gave important advices to the top management of arrogance. I was fired in 1992 although I was very correct for both!

I sued GLASTON to court for illegal, dirty and untrue dismissal. We solved the dispute in such a way that GLASTON agreed to give me the BTF patent rights, paid patent fees for some years and paid a small reimbursement. BTF would have been extremely profitable 1990’ies!

WHAT HAPPENED TO BTF?

GRUPPO FININD had a small glass machinery business called IANUA. GRUPPO FININD is now https://www.isoclimagroup.com/en/. I contacted IANUA. Mr. Alberto Bertolini, technical and commercial ”brains” of ISOCLIMA. He understood the potential of BTF immediately. I got quickly an order of customer who understood the process correctly. After this it was designed and manufactured. The glasses were impressive in 1990’ies.

BTF and its glasses

BTF photo in IANUA workshop just after the first glasses were made in 1995. The glass held by employees was Toyota Cressida rear glass. Bending depth 127 mm, cross curvature 4 mm, thickness 3,8 mm. Chief designer of BTF, ex Tamglass/GLASTON engineer is standing on left. Later he designed CONVAIR, flat tempering furnace. Next to him BTF inventor, Risto Nikander.

Several glasses were tested as per video from 1995 in IANUA workshop. https://www.youtube.com/watch?v=2cIsqubeJn0

Soon PININFARINA, a famous car designer in 1990’ies, bought prototype glasses made by BTF prototype.

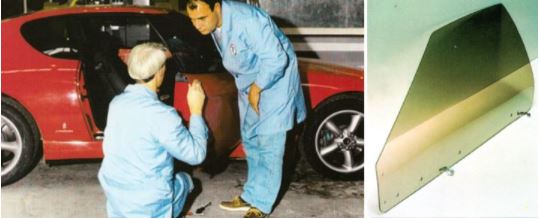

FERRARI door glasses

Many Ferrari owners wanted to change new “STOP SOL” glasses to their cars. The production took place in IANUA workshop by protype BTF. Door glass radius was 890 mm, cross curvature 4 mm. Soon glass sales were a small but profitable business to IANUA. IANUA did not deliver the prototype BTF to the customer but BTF was installed it to ISOCLIMA factory. IANUA made a new one for the customer.

BTF is producing excellent boat glasses in Canada and airplane glasses in USA. GLASTON made BTF 25 years later as per link https://glaston.net/releases/?id=55D9E431486F20E8, Risto Nikander tried to pressurize GLASTON to make BTF by complex, reverse curvature glasses by patent FI 88909, while still working in Tamglass/(GLASTON).

BTF prototype; even more impressive glasses

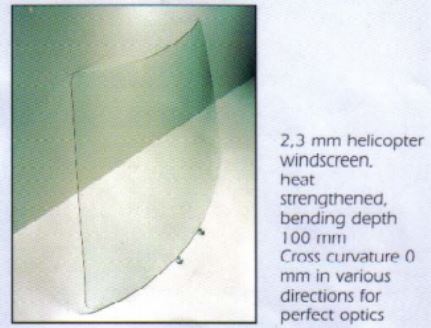

- SIKORSKY helicopter windscreen were manufactured in Los Angeles. Bending and heat strengthening was made in Japan, ASAHI, now ASG by vertical bending and tempering machine.

- When BTF was in ISOCLIMA factory preprocessed glasses were air freighted from the USA. One engineer and an inspector came to check the bending and heat strengthening quality. The glasses were air freighted back to USA for lamination and encapsulation.

Other inventions related to BTF

As BTF was a low capacity machine for short series, these invention were very important for it.

- Adjustable blowing area; saves energy + lowers tempering peak power.

- A shape adjustable quench head; saves tooling costs. (A better now available).

- A collar change system; for quick change over from product to product. See videos of BTF or ShapeWizard.

Why BTF sales were stopped?

- IANUA tried to make ”double chamber” machines to increase the capacity. It failed to transfer the glass from preheating chamber to bending and final heating chamber.

- First CONAVAIR was made in 1996. It was super by capacity ja excellent for the process. It was perfect convection heating chamber, especially for low emissivity glasses which were coming in 1990’ies. ISOCLIMA management understood that this could create a huge business business! See ”Competition” and ”Flat Glass Tempering”.

High capacity ”BTF”

Bending and tempering ”mode” was still going on in my head or subconscious. I invented this system in 2002.

- Patents were granted in Finland FI 115045 in 2005, EPO accepted them, China CN 100591634C in 2010. But never in USA.

- It would have been an excellent competitor GLASSTECH external press bender. I offered this to GLASTON in 2004, at the same time, when GLASTON tried to eliminate my “box construction” patent.

- With patent FI 88909 it would have challenged even GLASSTECH DBO 6 option.

For GLASTON HTBS is still the only bending and tempering machine, (instead of BTF, https://glaston.net/releases/?id=55D9E431486F20E8)

BTF got a chance in FINNTEMP as a ”ShapeWizard” in 2007.

BTF would still have a small market for special applications. FINNTEMP went bankrupt as 2 engineers wanted to make their own success story. Anything which was good in BTF and my ”product development plan” was not accepted. The only good result was a video https://www.youtube.com/watch?v=a5cS_CsYpY8

BTF used Tamglass Engineering gravity bending technology of ESU in 1993. With newest technology it would have been a real ShapeWizard.

Conclusion

90 – 99% of the safety glass technology is known. 10 – 1% simple inventions can make a big change.